Research and Development Design

In the realm of plastic packaging, we are not merely your packaging supplier but your trusted strategic co-creator. With deep insights into market trends and end-to-end R&D capabilities spanning concept design, mold development, and mass production optimization, we have successfully empowered numerous brands to launch best-selling packaging solutions. We significantly shorten your product time-to-market, helping you swiftly transform your product vision into tangible market competitiveness.

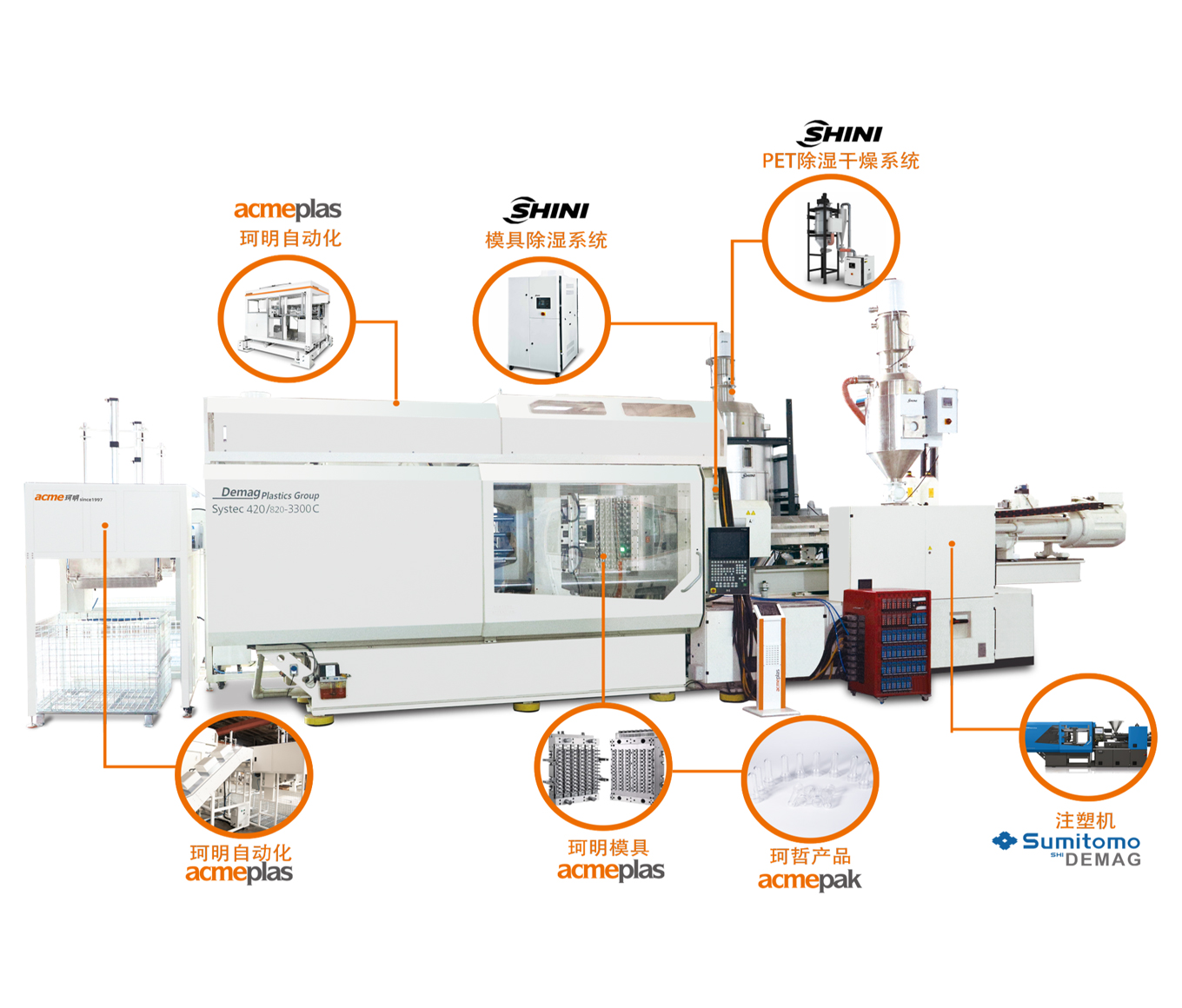

We possess deep expertise in core processes including injection molding, injection blow molding, extrusion blow molding, physical microcellular foaming, and in-mold labeling (IML). For instance, IML achieves a seamless, high-aesthetic appearance in a single molding step—offering environmental benefits, significant long-term cost savings, and built-in anti-counterfeiting protection. Physical microcellular foaming significantly reduces weight while maintaining strength, enhances thermal insulation properties, and helps clients lower costs while elevating product quality. Leveraging these mature processes, every creative concept can be transformed into a feasible, efficient, and cost-effective production solution.

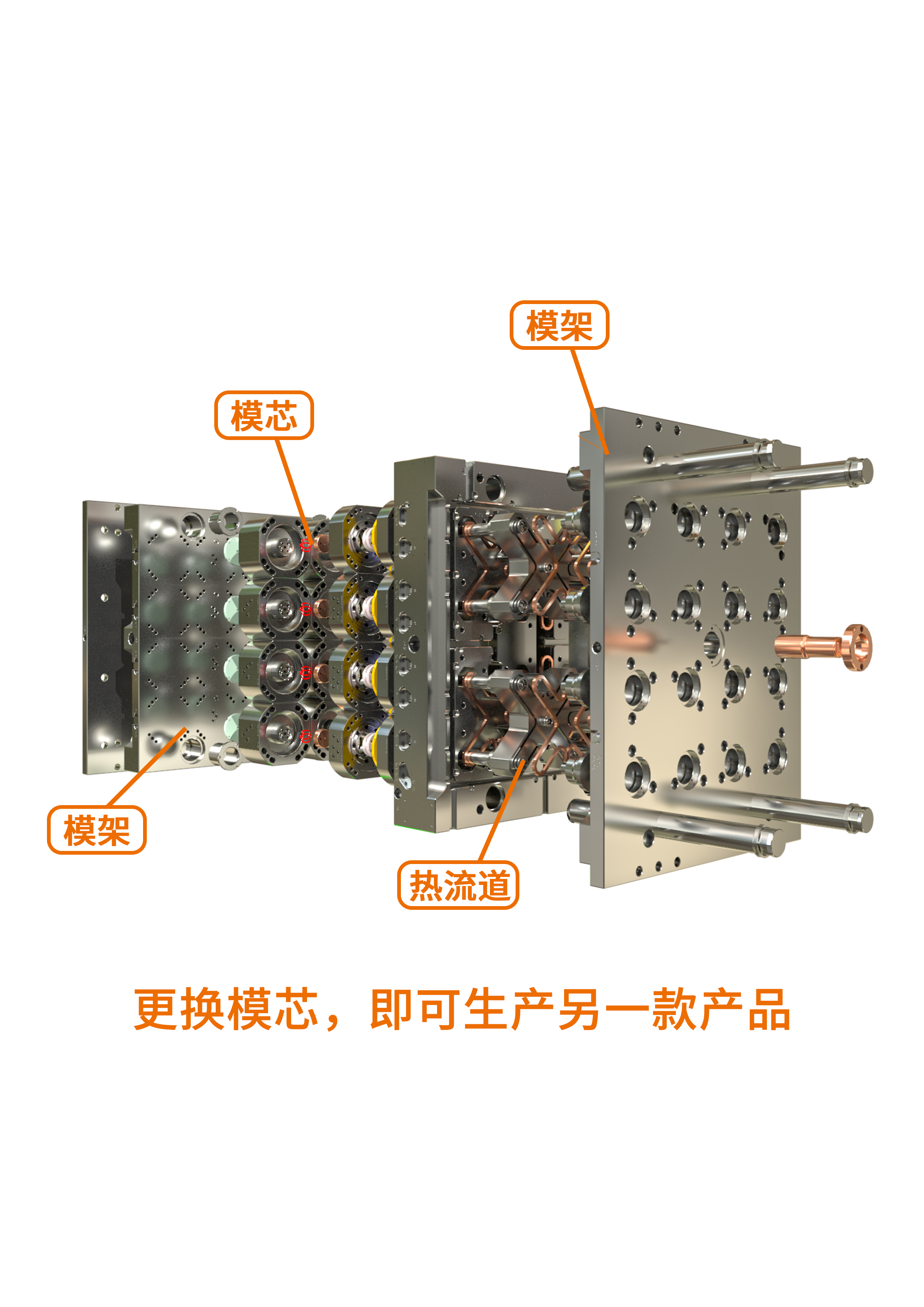

Our production equipment and molds feature advanced modular designs that enable rapid adjustment and switching to adapt to diverse production scenarios. With strong scalability, they require minimal modifications and low investment costs. This creates a highly efficient and flexible production system capable of handling orders of all sizes and custom requirements. It allows for swift responses to market changes, fulfills personalized customer needs, shortens time-to-market, and empowers clients to seize market opportunities.

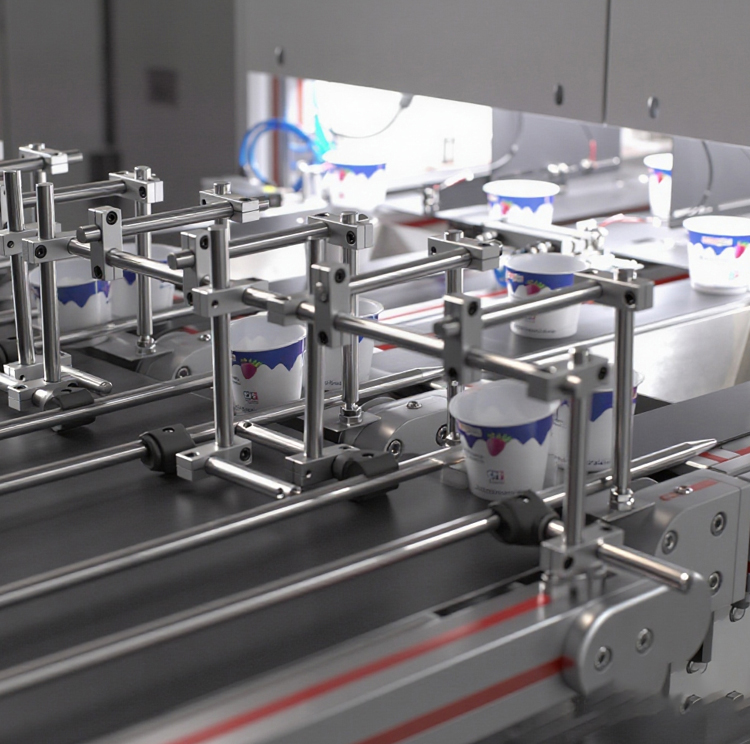

Leveraging our highly automated production line system, we achieve efficient and stable large-scale manufacturing, fundamentally ensuring consistent product quality. Equipped with intelligent online inspection and automated packaging systems, our production lines undergo real-time monitoring throughout the manufacturing process. This guarantees 100% inspection of all packaging products, maintaining a clean and contamination-free environment throughout. We precisely meet the stringent quality requirements for high-end packaging in sectors such as food and pharmaceuticals.

Quality is the lifeblood of an enterprise. Our “zero-defect” quality control ecosystem achieves 100% full inspection through online automated detection systems, maintaining a comprehensive yield rate consistently above 99.9%. For instance, in providing in-mold labeling packaging production for a certain brand, we utilized our online automated inspection system coupled with process closed-loop management. This approach reduced the client's PPM from the industry average of 800 PPM to below 50 PPM, achieving the client's quality control goal of “zero customer complaints.”

Worry-Free After-Sales Service

Delivery is not the end, but the beginning of a long-term partnership. Your dedicated team is always on standby to quickly pinpoint issues and provide actionable solutions. We regularly deliver data-driven optimization recommendations to help you continuously reduce costs and boost efficiency. We serve with dedication, walking alongside you every step of the way, all for lasting mutual success.