【Acmepak Innovation Technology - Physical Microfoaming Outside the Mold】Debuts at the 2025 Polyolefin Innovation and Technology Forum

Release Time:2025-11-07

Recently, the China Synthetic Resin Association and Milliken jointly hosted the 2025 Polyolefin Innovation and Technology Forum in Shanghai. On the first day of the forum, Wang Xingdong, founder of Acmeplas Group, shared the latest product from the group's subsidiary, Acmepak Packaging: in-mold physical micro-foamed food packaging.

To understand “out-of-mold physical microfoaming,” it helps to compare it with traditional “chemical foaming.”

Chemical foaming: A chemical foaming agent is added to the plastic raw material. Upon heating, the foaming agent decomposes to produce gas (such as nitrogen or carbon dioxide), forming bubbles. This method makes it difficult to control bubble size and distribution. Chemical foaming is not environmentally friendly and is unsuitable for food packaging.

Out-of-mold physical microfoaming:

Injection: During plastic melting, a special device injects a supercritical fluid (typically supercritical nitrogen or carbon dioxide) into the molten plastic.

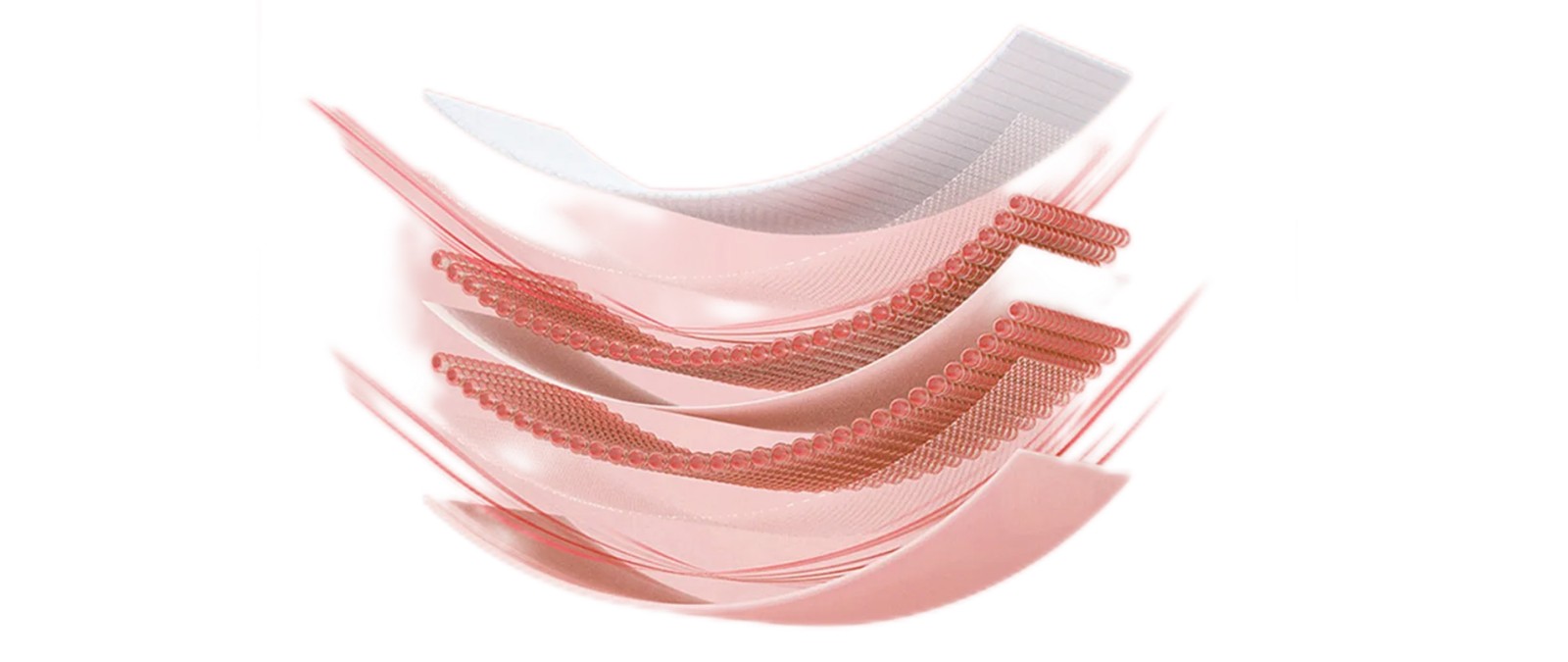

Mixing: The supercritical fluid and molten plastic mix thoroughly under high pressure, forming a uniform single-phase solution.

Molded Preform: This high-pressure mixture is injected into a cooled mold and rapidly chilled to form a solid preform with a specific shape. Due to the rapid cooling, the gas inside the preform cannot expand in time and is “locked” within the material.

Off-Mold Foaming: The molded preform is removed from the mold and placed into a high-temperature oven filled with steam or hot air. At elevated temperatures, the trapped high-pressure gas rapidly expands, forming countless tiny closed cells that increase the preform's volume.

The “micro” aspect lies in these bubbles, typically ranging from 1 to 100 micrometers in diameter, existing in vast numbers and distributed extremely uniformly.

Products and Applications

《Hot beverage cup》 《Dry-stirred noodles》

《Takeout box》 《Self-heating pot》

Out-of-mold Physical Microcellular Foam Materials vs. Traditional Dense Plastics

Product density reduced by 5%-30%; Exceptionally high dimensional stability with minimal warping and deformation; High mechanical strength and excellent toughness; Refined, premium-quality appearance and texture.

Exceptional Lightweighting

Achieves 10%-30% weight reduction while maintaining equivalent rigidity and strength.

Physical Comparison Group 1: (15% material savings)

Traditional packaging materials:28.12g Foam material:23.93g

Physical Comparison Group 2: (18% Material Savings)

Traditional packaging materials:28.45g Foam material:23.16g

Physical Comparison Group 3: (25% Material Savings)

Traditional packaging materials:48.37g Foam material:36.46g

全面的成本控制

Comprehensive Cost Control

Significantly reduced auxiliary costs, substantially extended insulation time, and enhanced eating experience

Excellent mechanical properties

♢High strength-to-weight ratio/stiffness-to-weight ratio: Superior strength and stiffness per unit weight for enhanced structural integrity

♢Exceptional impact resistance: Microcellular structure effectively absorbs and disperses impact energy, delivering outstanding cushioning protection

♢Reduced warping deformation: Uniform cellular structure throughout ensures balanced stress distribution during cooling for dimensional stability

We firmly believe that in-mold physical microcellular foam technology represents a pivotal pathway for the packaging industry toward high performance and sustainable development. We look forward to partnering with you to transform innovation into competitive advantage and jointly drive green transformation within the industry.

Let us work together to clothe your products in a smarter, lighter, stronger, and more eco-friendly “outer layer.”

Related Reading