A decade of honing the blade, “Craftsmanship and Innovation” illuminate the future.

Release Time:2025-02-18

In the fiercely competitive plastic packaging industry, Shanghai Acmepak Plastic Packaging Technology Co., Ltd., as a core enterprise under the Acme Group, shines like a dazzling new star. Navigating the market's waves with determination, it continues to radiate brilliance.

Since its establishment in 2013, Acmepak has dedicated over a decade to deepening its expertise in the industry. Starting with a single product line, it has progressively evolved into a comprehensive technical solutions provider covering diverse processes such as injection molding and bottle blow molding. Even amidst the challenging environment of the three-year pandemic and subsequent economic downturn, Acmepak has maintained robust growth momentum. In 2024, the company achieved a 15% year-over-year increase compared to 2023, with this year's performance projected to reach new heights!

01 Customer Trust: Partnerships Forge Success

Acmepak's success stems from the profound trust of its clients. “This trust is the reward for a decade of dedicated refinement,” remarked the General Manager of Kemei Group, capturing the essence of this partnership. Since its inception, Acmepak has remained focused on meeting the needs of leading brands, enhancing product value through technical expertise, process innovation, and customized services.

Today, Acmepak maintains long-term, stable partnerships with numerous globally renowned brands, including KFC, Wei Chuan, Junlebao, Kashi Dairy, Haidilao, Meiji, Want Want, and Xiang Piaopiao. Whether designing eco-friendly bottles for Kashi Dairy or developing spill-proof coffee cup lids for clients, Acmepak consistently upholds its core philosophy of “Innovation + Pragmatism,” delivering countless high-quality, efficient, and visually appealing solutions to the market.

Moreover, Acmepak maintains exceptionally stable partnerships with major clients, who consistently adopt its innovations upon launch. Currently, Acmepak is in discussions with brands like Yili and Mengniu, promising exciting developments ahead!

02 Technological Innovation, Driving Industry Transformation

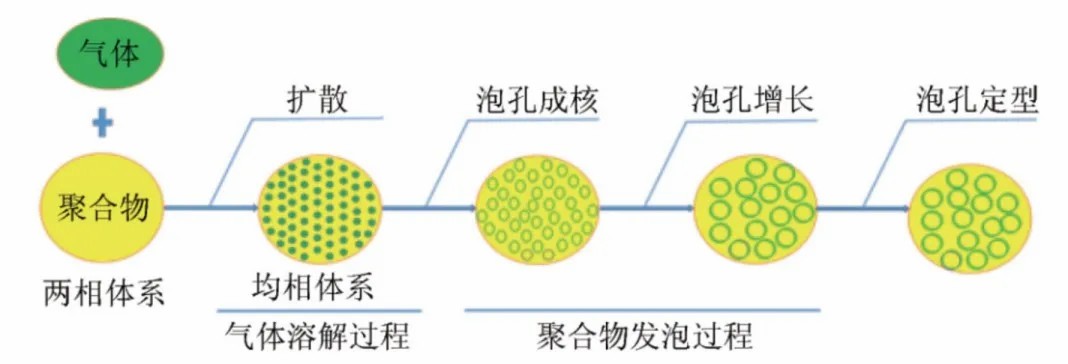

Amidst the wave of intelligent manufacturing, Acmepak wields technology as its spear and innovation as its shield, continuously pushing its own boundaries. Through collaboration with Europe, Acmepak has introduced advanced foreign technologies and built upon them to develop derivative innovations, successfully launching its physical micro-foaming injection molding technology.

Products manufactured using this technology not only deliver outstanding drop resistance and protective capabilities but also exhibit excellent thermal insulation properties. Concurrently, Acmepak has made significant strides in environmental sustainability, rigorously controlling everything from raw material selection to production processes, thereby substantially reducing both material consumption and energy usage.

The emergence of physical micro-foaming injection molding technology has injected powerful momentum into Acmepak's product line, enabling a qualitative leap in performance, quality, and aesthetics. This has further enhanced the company's competitiveness in the market and provided customers with more premium choices.

03 Production Capacity Upgrade to Meet Customer Demands

Currently, Acmepak operates nearly a hundred production systems, enabling it to supply high-quality products in large quantities to premium clients both domestically and internationally. Backed by the robust resources of the Kemei Group, Acmepak Packaging can swiftly augment its production equipment to accommodate rapidly growing order volumes, efficiently meeting customer demands.

To better accommodate expanding client demands, Acmepak will add production lines as necessary. Starting in 2024, the company will fully implement industrial transformation and upgrading, advancing automation and digital production to continuously enhance manufacturing efficiency and product quality.

04 Equipment Promotion: Challenging International Brands

This year, Acmeplas will establish dedicated departments to market equipment such as preform injection molding systems for brands like Wahaha and Nongfu Spring. Valued at tens of millions of yuan, this system demands cutting-edge technology and addresses dozens of technical challenges. Having achieved full operational success in December last year, Acmepak will now focus on optimizing the system's production capacity and energy efficiency.

Over the next three years, the company plans to develop, debug, and market 100 to 200 such systems, engaging in fierce competition with international brands to demonstrate the strength and responsibility of Chinese enterprises.💪

Moving forward, Acmepak will continue to drive innovation with technology as its engine and exploration as its foundation, delving into the boundless possibilities of the packaging industry. Each breakthrough redefines the concept of “artisan-driven intelligent manufacturing.” Let us collectively anticipate Acmepak achieving even greater brilliance in the plastic packaging sector!

Related Reading

【Acmepak Innovation Technology - Physical Microfoaming Outside the Mold】Debuts at the 2025 Polyolefin Innovation and Technology Forum

2025-11.07

Acme Group Conducts Fire Drill to Strengthen Safety Defenses

2025-06.26

Great News! Acmepak Wins the Advanced Award for Comprehensive Contribution in Lüxiang Town

2025-02.21