Continuous Innovation: [Physical Micro-Foaming Technology]—Empowering Packaging Cost Reduction and Product Upgrades

Release Time:2025-01-04

Physical Microfoaming Technology

— Empowering Packaging Cost Reduction and Product Upgrades

In today's fiercely competitive market, every 1% reduction in costs translates to an additional 1% profit margin for businesses. Imagine what it would mean if a technology could help you reduce material costs by up to 30% while simultaneously enhancing product performance and quality. Today, we introduce Physical Microfoaming Technology—a revolutionary innovation driving unprecedented transformation in the packaging materials industry. Let's explore its limitless potential together.

Diverse Core Products: Technology-Empowered Upgrades

We have consistently dedicated ourselves to the high-end packaging sector, cultivating a rich and diverse portfolio of core products.

These include in-mold labeling containers, thin-walled injection-molded products, folding spoons and forks, as well as preforms and injection-blow molding bottles. These products are highly recognized and favored in the market for their high quality and innovative designs.

The advent of physical microcellular injection molding technology has now injected powerful momentum into our product line. The application of this technology has enabled a qualitative leap in product performance, quality, and appearance, further enhancing our competitiveness in the market and offering customers more premium choices.

Focus on Physical Microcellular Injection Molding Technology

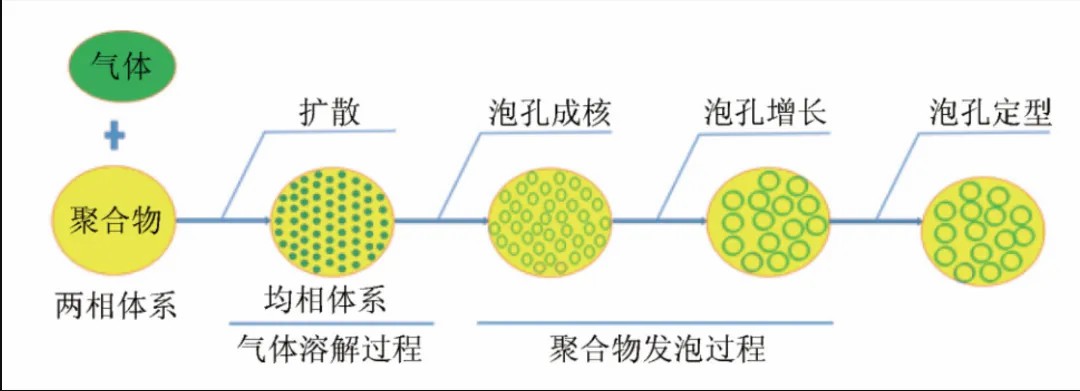

Physical microcellular injection molding technology represents an innovative process. During injection molding, precise control over the injection and expansion of physical foaming agents creates countless uniformly distributed microbubbles within the plastic melt. The presence of these microbubbles delivers numerous unique advantages to the final product.

Products manufactured using this technology achieve wall thicknesses precisely controlled around 2.34 mm. This level of precision significantly enhances structural strength, delivering robust drop resistance and superior protective capabilities. The casing effectively withstands everyday impacts and compression, providing reliable protection for packaged contents.

Exceptional Performance: Savor Deliciousness and Eco-Friendliness

Physical micro-foaming injection molding technology endows our products with outstanding heat retention properties. Whether it's steaming hot takeout noodles, succulent dumplings, warming beverages, or convenient self-heating meals, our packaging boxes lock in heat for extended periods, delivering flavors as fresh as when they first came off the stove.

On our environmental journey, we courageously embrace social responsibility, meticulously selecting raw materials and rigorously controlling every stage of production to strictly adhere to stringent environmental standards throughout the entire process. This masterpiece of craftsmanship not only significantly reduces raw material consumption and energy waste, actively contributing to environmental protection through concrete actions, but also achieves effective cost control by optimizing processes. This creates a win-win situation of energy conservation, reduced consumption, and lower costs, truly embodying the essence of green development.

Embarking on a New Journey in Premium Packaging

By choosing our physical micro-foam injection molding packaging products, you gain more than just packaging—you gain the perfect fusion of quality, sustainability, and innovation. It represents our relentless pursuit of premium packaging and our solemn commitment to our customers.

Moving forward, we will continue to delve deeper into the realm of smart manufacturing, driving constant innovation to deliver packaging solutions that exceed your imagination. Let us join hands to write a brilliant chapter in premium packaging, enriching life with even more brilliance.

Some images sourced from Baidu. Remove if infringing.

END

Related Reading

【Acmepak Innovation Technology - Physical Microfoaming Outside the Mold】Debuts at the 2025 Polyolefin Innovation and Technology Forum

2025-11.07

Acme Group Conducts Fire Drill to Strengthen Safety Defenses

2025-06.26

Great News! Acmepak Wins the Advanced Award for Comprehensive Contribution in Lüxiang Town

2025-02.21